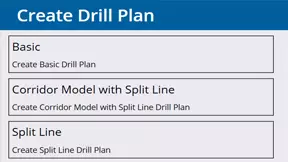

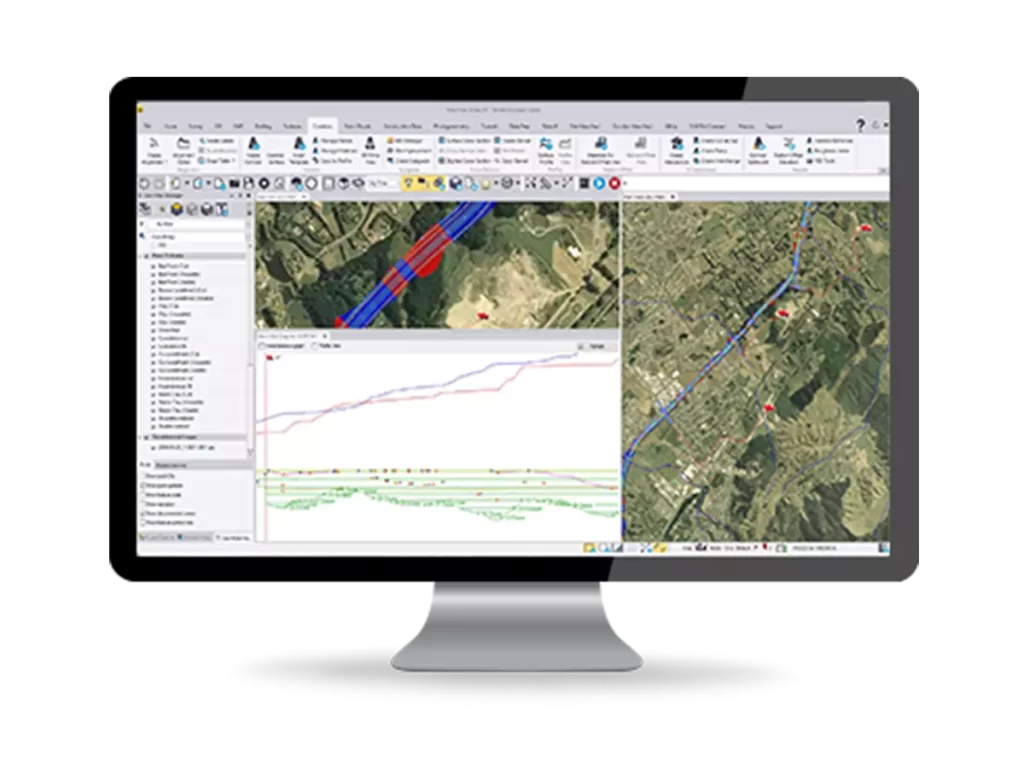

Make better decisions, decrease costly mistakes, and increase efficiency in the office and on the jobsite. Powerful tools help you quickly and easily create accurate, integrated 3D constructible models for construction surveying and machine control.

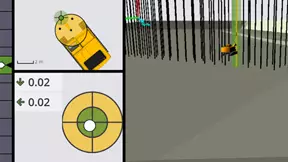

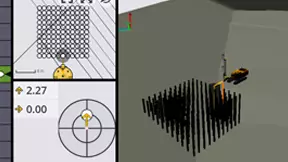

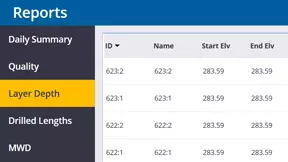

Optimise production and revenue for drilling, piling and dynamic compaction operations. All day, all night and under almost any conditions.